With much activity going on in the resources sector, the spike in commodity prices induces a surge in job vacancies across Australia, as well as increased focus on fleet management technology.

Despite its extreme temperatures and arid, barren appearance on the outside, below the surface, the Outback is a prolific source of natural resources, such as iron, aluminium, manganese and uranium ores, as well as major deposits of gold, nickel, lead and zinc. This makes the Australian Oil, Gas & Mining sector one of the biggest economic drivers in the country, prompting new employment opportunities for innovative, tech-savvy talent.

According to Hays Recruitment, the overarching theme in positions advertised in the industry for 2017 revolve around efficiency and productivity. In other words, positions that ensure the smooth-running and optimal time management of supply chain – from the pit to the port. Mining Engineering graduates were also featured on top of the list, as the focus on renewable energy and technological growth has become nucleic to resource extraction.

It is evident that the Australian Oil, Gas & Mining industry is undergoing a significant transformation, in what concerns technology and workforce, and these changes bring many untapped pressures into the light. Outcome management and risk assessment are on top of minds for Process Safety Managers and HSE, striving to harmonise and improve operational standards together with workplace engineering. Automation has also become a more prominent staple in the industry, as it helps increase the bespoke efficiency and safety in mineral extraction, as well as bring substantial cost savings.

Remote-controlled machines, fleet telematics, Internet of Things and big data analytics are all key players in today’s mining landscape, combining autonomy, remote management and precise metrics for optimal efficacy. Adapting technology and safety processes to the workforce is becoming increasingly mandated by the Work, Health & Safety (WH&S) policies, especially with regards to working in remote locations.

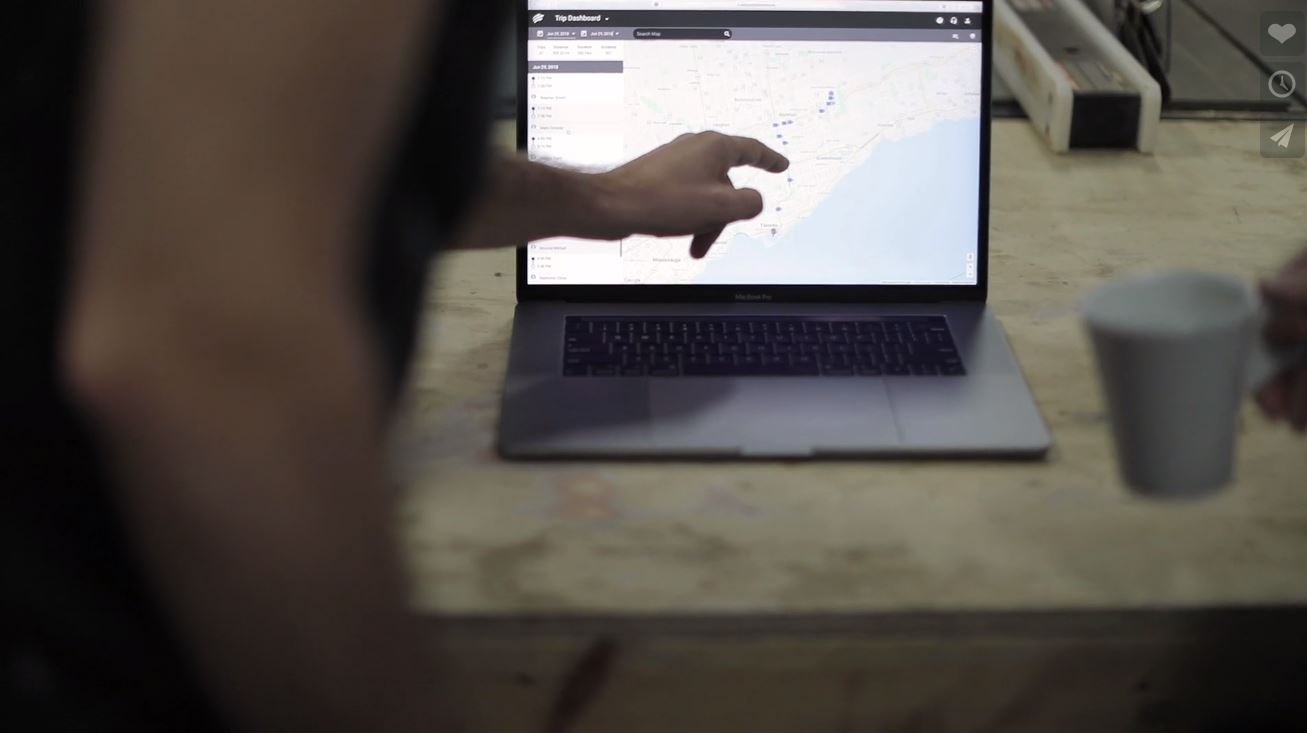

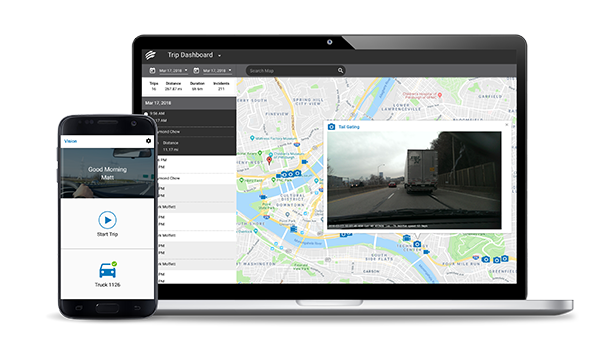

It is no surprise that today’s advanced fleet and asset management solutions, like Fleet Complete, are an ideal resource for companies and corporations to remotely monitor in-field activity, run a more eco-friendly fleet, and be alerted to any duress or unauthorised action at once.

These solution platforms deliver the coveted 360-degree visibility into all operational aspects, including the supply chain, and help ensure employee safety, particularly for lone workers in the Outback.

They incorporate:

- In-Vehicle Monitoring Systems (IVMS)

- GPS asset tracking

- Multi-use sensors

- Instant two-way communication

- Geofencing

- Emergency devices

- Journey Management Centre

- Iridium Satellite modules for limited cellular coverage

Engine-connected diagnostic modules automatically notify of any vehicle or equipment malfunction and required maintenance, and even indicate fuel levels, eliminating time-consuming manual check-ups.

Yet, even if physical labour is gradually becoming less of a necessity, the need for mobile asset management and maintenance grows, uncovering a new avenue for job creation. With comprehensive IoT platforms and robotics continuously permeating the mining space, the industry’s employment landscape is changing accordingly to support the in-coming technologies.

“You still need people in there to monitor where they go, to tell them where they should be going and what they should be doing, even though a lot of that scheduling is being done automatically,” notes Dr Carla Boehl, Curtin University’s School of the Mines, expressing great optimism for her students’ gainful employment post-graduation.

Safety, efficiency and productivity are the key milestones of innovation in the sector and provide big opportunities for the future generation of mining professionals.